“Water-Loving” aka Hydrophilic Waterstops

The term hydrophilic means “water-loving.” A good example is a sponge that absorbs water (or other polar fluid) and swells. At their most basic level, hydrophilic waterstops absorb moisture, grow in size, and seal the concrete construction joint.

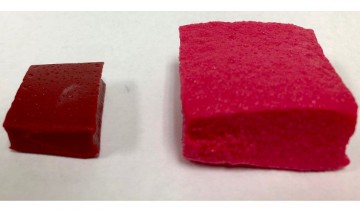

Hydrophilic waterstops sell in rolls or strips. The profile is usually a small rectangle or trapezoidal shape, with 3/4” x 1” being somewhat standard. These strips are adhered to existing concrete using an adhesive or primer, or alternately concrete nails at 12” on-center spacing. This adhesion is essential, as only three sides of the waterstop get exposed to fresh concrete. If the waterstop displaces during the concrete pour, it can quickly lose most of its effectiveness.

Commercially available for several decades, hydrophilic waterstops have long track records, albeit not always positive. Take great care at the specification level to ensure your project meets this range of product’s relatively narrow application scope.

Hydrophilic Waterstops — The “Pros”

The most significant advantage of hydrophilic waterstops is their ease of installation — the products get glued in place at the cold joint, and concrete is then cast on top of them (the second pour). The installation efficiency of this class of products makes them a favorite amongst contractors in the field

Another “pro” is their relatively low cost. A “typical” sodium bentonite-based waterstop is approximately $2.00 per linear foot, and a “typical” chemical-modified chloroprene rubber waterstop is $6.00 per linear foot. When combined with the low labor cost, strip-applied hydrophilic waterstops are time and money savers.

Hydrophilic Waterstops — The “Cons”

To read the manufacturer’s product literature, you would think they are indeed the perfect waterstop product. Cheap and easy to install, high head pressure-resistant, and low material cost. These products are not the panacea the manufacturers claim, and the essential information concerning their use is often not published. For instance, a leading manufacturer of hydrophilic waterstop states the following minimum requirements on their datasheet:

- 8-inch thick concrete or greater

- A double row of reinforcing steel

- 3,000 psi concrete or greater

- 3 inches of concrete coverage on all sides of the waterstop (minimum)

- Non-moving construction joints only

These requirements seriously limit the project designer. Few concrete projects consist of just construction joints, and eight-inch thick concrete is rare in residential and light commercial construction. The first four prevent the hydrophilic reaction (waterstop swelling in the presence of water) from cracking or blowing out the concrete. The leading manufacturer of bentonite-based waterstops includes 75% sodium bentonite into the manufacture of their product. This high concentration of bentonite allows the product to rapidly swell when exposed to water, which is good as it will seal the joint more quickly. However, this high concentration of bentonite can also create problems such as concrete cracking or even the potential of blown-out joints due to the internal pressure of the rapidly expanding waterstop and the low tensile strength of uncured concrete.

Another limitation is the product’s inability to swell as intended in fluids other than water. All of the commercially available hydrophilic waterstop products have published data for swell ratios; however, this data is for potable water (often distilled) and saltwater. Since the products need to swell to seal the concrete joint, a designer for a non-water facility (such as secondary containment of petroleum products) can not specify hydrophilic waterstops with confidence as they will not swell as intended and may deteriorate. The American Concrete Institute recommends against using hydrophilic waterstops for fluids other than water (ACI 350.2R-04).

Hydrophilic Waterstops — Butyl/Bentonite

The first hydrophilic waterstops sold commercially were a mixture of clay and rubber. Sodium bentonite clay is the hydrophilic component of the product. Butyl rubber serves as the cohesive, tacky base.

Bentonite-based hydrophilic waterstops are susceptible to product disintegration over the long term, especially when the moisture or saturation conditions are cyclical. The continual expansion/shrinkage/re-expansion causes the products to break down, and the bentonite migrates from the butyl rubber, leaving a smaller, cracked, non-expandable product.

Waterstop products containing less bentonite are less likely to break, blow out the concrete joint, and are less likely to break down over time from bentonite migration. However, they also swell slower and less volumetrically. Reduced bentonite waterstops should not be used in saltwater as their hydrophilic reaction is limited.

Sodium bentonite-based hydrophilic waterstops are still commercially available today. However, their use has diminished by the advent of chemically modified chloroprene waterstops that provide the required hydrophilic expansion with water, without the degradation and breakdown of the natural clay product.

Hydrophilic Waterstops — Modified Chloroprene Rubber (MCR)

Not all hydrophilic waterstops use bentonite clay as their hydrophilic agent. Modified chloroprene rubber waterstop is 100% rubber and contains no bentonite. MCR waterstops are chemically modified to swell in water, but not to the point of disintegration, eliminating the wet/dry cycling problem that affects the bentonite-based waterstops. MCR waterstop holds up much better over time. Other product features make chemically modified chloroprene waterstops the right choice for a variety of applications. However, this class of hydrophilic waterstop also suffers from many of the same weaknesses as the more inexpensive bentonite-based waterstop products — Namely, the inability to swell in fluids other than water, slow swell time, and the lack of expansion and contraction joint functionality.

JP Specialties Earth Shield® Waterstop and Jarco Supply

JP Specialties is the leader in waterstop technologies. When major engineering firms need to ensure the integrity of their concrete structures, they turn to Earth Shield® Waterstop and JP Specialties. Likewise, Jarco Supply is proud to be the supplier of choice for all of the Earth Shield® Waterstop products.